How to MIG weld

MIG has been the most popular

welding process for decades, for both professional welders and

hobbyists. It’s fast, strong, versatile and fairly easy for most people

to learn. Because it’s such a great process, there’s a steady stream of

newcomers determined to learn. In this article, we’ll cover the basics —

and it will be a good refresher for those who already have some welding

experience.

Let’s

start with a definition: MIG stands for Metal Inert Gas welding. In the

industry it’s called Gas Metal Arc Welding (GMAW) — but the term MIG

welding is much more common, so we’ll use that here.

Setting up your equipment

MIG

welding uses a power supply providing constant voltage, most commonly

Direct Current Electrode Positive (DCEP). The power supply uses

transformers and rectifiers to modulate line voltage, which stabilizes

the arc and provides good arc starts — as well as incorporating

circuitry to protect against overloading. A work clamp connects the

material being welded to the power supply, completing the circuit. There

is a spool of wire, usually housed inside the power supply case, along

with a drive mechanism to feed the wire through the cable, toward the

gun.

The

hand-held gun is the “business end” of a MIG machine. The gun has a

trigger that controls several functions simultaneously. Pulling the

trigger electrically energizes the welding wire and starts the motor

drive, feeding the wire automatically as you weld. MIG welding requires

the weld to be shielded from the atmosphere. This is often done by

directing shielding gas over the weld area — and the flow of gas is also

controlled by the trigger on the gun. A flux-cored wire is used for

some MIG welding applications, either alone or with a gas shield.

The

majority of MIG welding is done with a gas shield — carbon dioxide and

argon/CO2 mixes are the most common. The gas bottle has a regulator or

flowmeter to set the gas flow. There are many variables here, but a good

rule of thumb for light-duty welding is to use about 20 cubic feet per

hour of gas flow. Once you’ve developed some skill with the gun, you can

experiment with optimizing the amount of gas used.

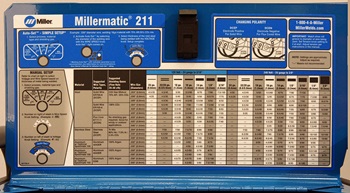

Before

making a weld, there are two essential settings that must be made on

the welder: the voltage and the wire feed speed. Nearly every MIG welder

has a chart — including my Millermatic® 211

— often just inside the hinged access cover, which gives you the

suggested settings. These are based on the material type and thickness,

and the diameter of the filler wire being used. These values are used to

adjust the settings on the face of the machine.

Miller pioneered the Advanced Auto-Set™ technology,

which allows you to simply set the process, the material thickness and

wire diameter, and the machine adjusts the settings automatically. This

has worked so well for me that I haven’t read a chart in years!

Best practices for MIG welding

The

material needs to be clean to get a good weld, and any grease or oil

should be removed before using abrasives. MIG welding is more tolerant

of minor surface contaminants than TIG welding, but the cleaner the

metal, the fewer problems you’ll have. The best welders are quite fussy

about surface preparation, and cleaning the base metal is a good habit

to get into. I often use sanding disks or a non-woven abrasive for

cleaning rust, paint or scale off the metal.

Setting

up the machine and preparing the material is the easy part. The way you

hold and move the gun is the key that governs the quality and

appearance of your welds. Whenever possible, it’s best to use a

two-handed grip on the gun and to support your hands, wrists, forearms

or elbows in a way that allows you to move the gun smoothly, while

maintaining precise control. The position of the gun and the distance

from the gun to the work are crucial.

The

farther the gun is held from the work, the farther the wire has to

extend to meet the metal being welded. The length of the wire between

the gun and the base metal is called the stickout

and has a BIG effect on the quality of the weld. Normal stickout is

usually around 3/8 inch. If you allow the gun to creep farther away from

the metal it increases the stickout, which puts less heat into the

metal and can decrease the coverage of the gas shield.

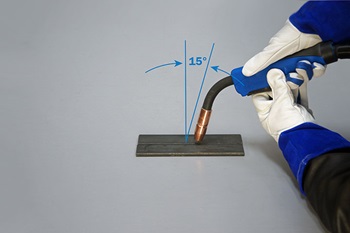

I

normally push the puddle when I weld. Since I’m right-handed, that

means the motion of the gun is toward my left. In most cases, the gun

should be angled slightly in the direction of motion. This is called the

travel angle, and 15 degrees is a good place to start.

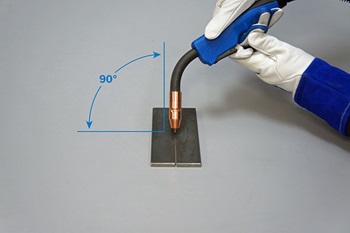

Looking

at the gun from the end of a seam, the angle of the gun to the work is

called the work angle. For a butt joint, 90 degrees is ideal.

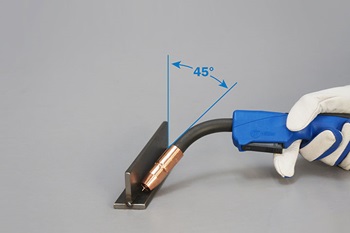

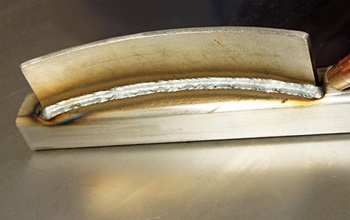

For

a 90-degree fillet weld, the gun is normally held at 45 degrees,

although this may need to be modified for thin metals. If a fillet weld

is configured as an inverted T (like the photo below), the horizontal

portion can dissipate heat on both sides of the weld. The vertical

element ends at the weld, so it can’t dissipate as much heat; this

sometimes causes burn-through. Angling the gun slightly away from the

vertical element will help in situations like this.

The

speed you move the gun is very important too. Going too slowly builds

up an oversized bead and going too quickly may diminish penetration.

Some welders hold the gun steady as they progress along the joint, but

there are a variety of techniques for weaving or oscillating the gun

that may be beneficial. There are no hard-and-fast rules here and I

encourage you to experiment with subtle changes in the way you move the

gun, paying close attention to how each change affects the weld. You can

learn a lot by talking to and observing other experienced welders.

So

how do you judge the quality of a weld? Ideally, the weld bead should

be slightly crowned, with the toes or edges of the bead flowing nicely

into the base metal. There should be full penetration, but not so much

that there is excessive bleed-through on the back of the joint. The

width and height of the bead should be fairly consistent from one end to

the other, and there should not be any craters or voids in the weld

bead. Many people test their practice welds by holding a welded part in a

vise and bending the joint until it breaks. Ideally, the metal NEXT to

the weld should fracture before the weld bead does.

It

takes a lot of practice to get your welds to meet all these criteria —

but the more time you spend with your helmet down, carefully coaxing the

gun along its path, the better your welds will get!

Additional resources

With

support from Miller, I made a 70-minute video titled “MIG Welding Made

Easy.” This video gives comprehensive coverage of the points listed

here, plus a great deal more. This is available to stream or download

from my website:

https://covell.cinevee.com/mig-welding-made-easy